Safety Management Plan 101: A Beginner's Overview

One of the foundational tools for keeping safety in the workplace is the Safety Management Plan (SMP). It is a comprehensive document outlining an organisation's approach to identifying, preventing, and managing potential safety incidents and hazards. Here's a beginner's overview of the basics of a SMP and why it's a great addition for businesses of all sizes.

Definition of a Safety Management Plan (SMP)

A safety management plan (SMP) outlines specific safety arrangements and requirements for a given project or activity. It is part of an organisation's broader Work Health and Safety (WHS) management system. For example, in construction, an SMP outlines the safety measures that will be implemented on-site to protect workers and visitors.

SMP vs SMS

A safety management system (SMS) is often confused with a safety management plan. While they are similar, there are distinct differences between the two.

How Do They Differ?

- Scope: A safety management system covers all aspects of an organisation, while a safety management plan focuses on specific projects or activities to manage safety performance.

- Mandatory Requirements: A safety management system is compulsory for organisations to comply with health and safety regulations, while a safety management plan may not be required but is highly recommended for effective risk management.

- Flexibility: A safety management system provides the overarching framework and can be tailored to an organisation's needs. In contrast, a safety management plan is more specific and must align with the SMS.

- Longevity: A safety management system is a long-term strategy for managing health and safety, while a safety management plan is shorter-term, focused on a specific project or activity.

- Regulations: A safety management system is regulated by local and international safety standards. In contrast, a safety management plan may have more flexibility.

Is SMP the Same As the WHS Management Plan (WHSMP)?

A Safety Management Plan (SMP) is often referred to as a Work Health and Safety (WHS) Management Plan, particularly in the context of Australian regulations. However, while they are essentially the same, the terminology used may depend on the specific industry or regulatory context.

For example, in Queensland, Australia, the term WHS Plan is used for construction projects. Under the Work Health and Safety Act 2011, the principal contractor of a contractor for construction or project must draft a written work health and safety (WHS) management plan for the workplace before commencing work on the project.

SMP may be used in other industries, such as mining or manufacturing, to refer to a similar document outlining safety measures and procedures. Regardless of the terminology, the purpose and components of these plans remain consistent.

Who is Required to Have a Safety Management Plan?

While the specifics of safety management plans may vary depending on industry and local regulations, any organisation with employees operating in a potentially hazardous environment must generally have a safety management plan. For example:

- Construction companies

- Mining operations

- Manufacturing plants

- Transportation companies

- Healthcare facilities

- Major Hazard Facilities

Importance of a Safety Management Plan

Why are SMPs important for businesses? Put simply, they provide a proactive approach to managing health and safety incidents in the workplace. In addition, having a well-developed SMP can help organisations with:

Compliance with Regulations

One of the most crucial reasons for having a safety management plan is to comply with local and international, safety rules and regulations. An SMP is a legal requirement on certain construction sites in Australia, and failure to have one in place can result in penalties for the person or organisation. Additionally, not complying with safety regulations can lead to severe injuries or fatalities in the workplace.

Risk Reduction

The SMP identifies potential hazards assesses risks and implements controls to prevent accidents. This systematic approach to safety helps reduce the risk of work-related accidents and illnesses, thereby minimising absenteeism and turnover rates. It also protects the organisation's reputation and brand image.

Contractor Health and Safety

The Safety Management Plan aims to ensure all site Work Health and Safety policies and procedures are met by each contractor. As most construction projects involve multiple contractors, an SMP is crucial for ensuring all parties involved comply with safety measures, rules and regulations.

Continuous Improvement

An SMP is not a one-time document but an ongoing process. You should regularly review and update it to reflect changes in the workplace, regulations, and technology. Gathering feedback on the effectiveness of the plan's through KPIs allows for continuous improvement. It ensures that specific health and safety measures are always up-to-date.

Components of a Safety Management Plan

For health and safety management in the workplace, an SMP needs to cover several key components.

- Scope and Objectives: The SMP should outline the plan's scope, which may be specific to a project or activity. This section of the detailed plan also sets out the overall objectives and goals for managing health and safety responsibilities in the workplace.

- Roles and Responsibilities: This section outlines who is responsible for safety on-site. For construction work, for example, the principal contractor may be responsible for implementing and monitoring the SMP and the workers for following procedures. The plan should also include the names, positions, and health and safety responsibilities of all persons at the workplace whose positions or roles involve specific health and safety responsibilities.

- Hazard Identification and Risk Assessment: This key element identifies potential workplace hazards. After identifying hazards, the next step is undertaking a risk assessment to allow for appropriate controls to be implemented.

- Risk Control Measures: Safety committees, or safety representatives place control measures to minimise or eliminate the risk of hazards. An SMP should outline the specific controls that will be used to mitigate risks in connection with the project or workplace. The plan should also detail the arrangements for collecting, assessing, monitoring, and reviewing safe work method statements at the workplace.

- Emergency Response Plan: In the event of an emergency, a well-developed emergency response plan is vital and should include arrangements for managing any work health and safety incidents that occur.

- Training and Induction: All workers must be trained on the contents and procedures outlined in the SMP. The principal contractor should also ensure that each person carrying out construction work in the project is made aware of the content of the plan for the workplace before starting work.

- Consultation and Communication: An effective SMP involves consultation and communication between all workers, contractors, and stakeholders. The plan should detail the arrangements in place for consultation, cooperation, and the coordination of activities.

- Reporting and Record-Keeping: All incidents, accidents, near misses, and hazards should be reported and recorded on time. Keeping accurate records allows for ongoing analysis and improvement of the SMP.

- Review and Audit: An SMP is an ongoing process and should be regularly reviewed and audited by the principal contractor to ensure that it remains up-to-date. Everyone on site should be made aware of any revisions.

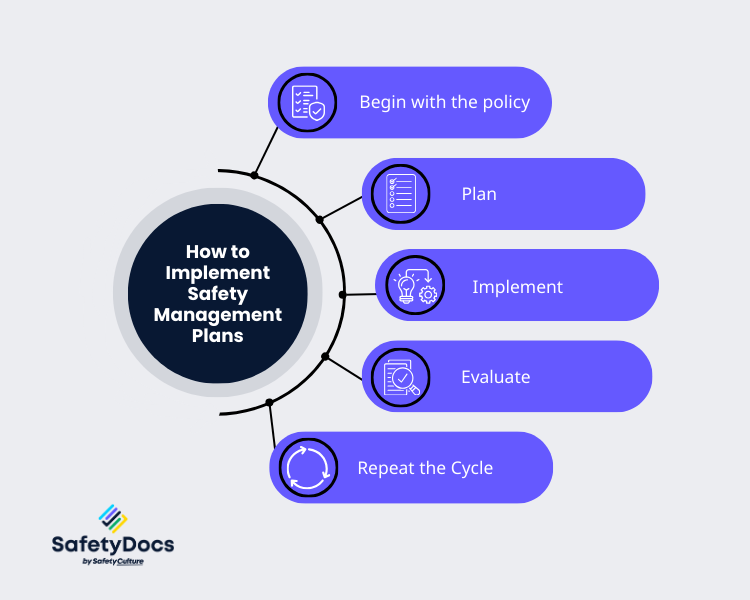

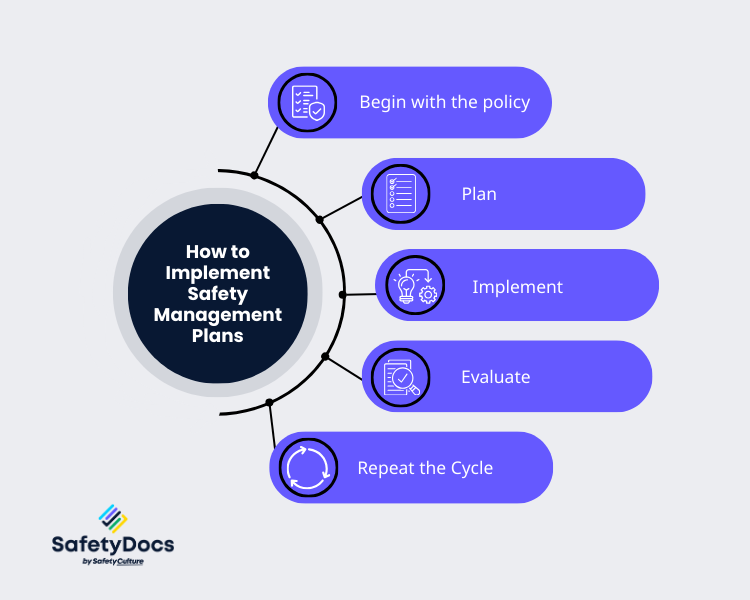

How to Implement them?

You now know what the components of an SMP are, but how do you implement them? Here are some steps to follow:

- Begin with the policy: Establish your vision, mission, values, and goals for safety management. Communicate these to stakeholders and obtain their support.

- Plan: Identify and analyse hazards and risks, determine legal requirements, develop standards and procedures, and allocate resources.

- Implement: Train workers on safety plans and expectations, provide necessary tools and information, and communicate regularly with them.

- Evaluate: Collect data on safety outcomes and processes and measure against objectives and indicators.

- Repeat the Cycle: Monitor, review, and improve the SMP while seeking stakeholder feedback.

Evaluating the Effectiveness of a Safety Management Plan

After implementing an SMP, it is crucial to evaluate its effectiveness. This can be done through key performance indicators (KPIs) such as:

- Incident rates: The number of incidents per a specific period, such as injuries or fatalities.

- Near miss reporting: The number of near misses reported and addressed can indicate the effectiveness of hazard identification and control measures.

- Worker satisfaction: Regularly survey workers to assess their perception of workplace safety.

- Compliance: Monitor compliance with safety protocols and regulations.

- Training: Monitor the completion of induction and ongoing training to ensure all workers possess the required knowledge and skills.

SMP for Industry-specific Needs

Different industries have unique safety requirements; an SMP should be tailored to address these needs. Save time and effort by using industry-specific SMP templates from SafetyDocs by SafetyCulture.

- Construction Management Plans

- Environmental Management Plans

- Hazardous Substances Management Plans

- Warehousing Management Plans

Safety professionals can trust these templates as experts develop them and are compliant with relevant regulations. We offer safety documentation templates, including safe work method statements, safety policies, and risk assessments that can be easily customised to suit your needs.

Whether you are new to safety management or looking to improve your existing SMP, these templates can be a valuable resource. Contact us to learn how SafetyDocs can help you create a comprehensive SMP for your workplace.

Our team of experts is dedicated to providing accurate and informative content. Craig Cruickshank, our senior HSEQ advisor at SafetyDocs by SafetyCulture has reviewed this blog post to ensure the highest level of quality.

Learn more about Craig's work on LinkedIn for more industry insights.

Available for instant download and supplied in fully editable MS Word format for use in your business.

Please note that the above information is provided as a comment only and should not be relied on as professional, legal or financial advice.